From exploring alternative energy sources to developing new technologies for the production, generation and utilization of energy, the EMS Energy Institute is involved in almost every aspect of energy research. This section highlights the diversity of some of our ongoing projects. This section is by no means an exhaustive list of projects.

Researchers aim to design new approach to hydrogen storage

Researchers aim to design new approach to hydrogen storage

Hydrogen is a clean energy carrier and has the potential to significantly reduce dependence on foreign oil and reduce carbon emissions. In order to advance the use of hydrogen and fuel cell technologies in transportation, stationary power, and other applications, storage is a key issue that needs to be addressed. Angela Lueking, assistant professor of Energy and Geo-Environmental Engineering, and a team of researchers, including John Badding, professor of Chemistry; Vincent Crespi, professor of Physics and Materials Science and Engineering; and Semih Eser, professor of Energy and Geo-Environmental Engineering, are in the initial phases of a project that will explore hydrogen trapping in carbon cages through repulsive interactions.

The project, funded by the Department of Energy (DOE), is in response to a need to develop alternative materials and ideas to maximize hydrogen storage. Current approaches face many challenges and have been unable to meet DOE hydrogen storage goals. The traditional adsorption mechanisms for solid-state storage of hydrogen, physisorption and chemisorption, depend intrinsically on attractive interactions and have limits that make them far from ideal for reversible practical room temperature hydrogen storage. The physisorption, or physical adsorption, of hydrogen onto substrates produces a bond that is too weak. However, chemisorped hydrogen can have too strong of a bond and the hydrogen desorption is often too slow.

This project aims to design a new approach to hydrogen storage with carbon hydrogen cage structures, or clathrates, based on previous observations that suggest a unique carbon-hydrogen interaction. Researchers are working to provide novel chemistry, which will be used to create a material consisting entirely of hydrogen trapped in carbon cages. This carbon-hydrogen material could provide a solution for the current hydrogen storage challenges.

Researcher explores process for producing military fuel from domestic resources

As a domestic resource, coal is an appealing fuel source and researchers have been looking at ways to expand its use, especially in areas that would result in the long-term replacement or reduction of the use of imported petroleum. For years, Penn State researchers have been exploring the production of a military logistic fuel JP-8 from coal through several novel processes, which allow the production of JP-8 from coal to be more energy efficient, economical and environmentally friendly.

Xiaoliang Ma

Dr. Xiaoliang Ma, senior research associate, EMS Energy Institute, is working on one such project, supported by the Defense Advanced Research Projects Agency (DARPA), that explores a novel process for converting coal to JP-8, instead of the conventional direct and indirect coal liquefaction processes. Dr. Ma’s work focuses on converting coal-derived light olefins to JP-8, which is one of the key steps in the proposed method for ultimately producing this military logistic fuel from coal and moving the United States toward greater energy independence.

Light olefins can be used to produce liquid hydrocarbon fuels, such as gasoline and diesel; however, no literature has been found about successful conversion of the light olefins to the military logistic fuel JP-8 because the resulting fuels lack needed characteristics. The major challenge to converting light olefins to JP-8 is in increasing the molecular weight of the hydrocarbons and in synthesizing the liquid hydrocarbons with the molecular structures needed for JP-8, such as cycloparaffins (hydrocarbon compounds with rings of carbon atoms). Cycloparaffins with a carbon number from 9 to 16, meaning they have 9 to 16 carbon rings, are the ideal JP-8 components because they have excellent low-temperature fluidity, high volumetric energy content, good combustion quality, and good oxidation and thermal stability, all important characteristics in a fuel that could be exposed to harsh conditions.

The main objective in the conversion of light olefins to produce JP-8 is to explore the feasibility of using a novel process and catalysts for the production of this military logistic fuel from light olefins derived from coal. This joint project is also looking at how to make the conversion process more energy efficient, economical, and environmentally friendly. In order to accomplish these goals, researchers are developing a new two-step process, to synthesize the liquid hydrocarbons with a high concentration of cycloparaffins and a boiling point in the range of 150 to 300 degrees Celsius (302 to 572 degrees Fahrenheit).

The main objective in the conversion of light olefins to produce JP-8 is to explore the feasibility of using a novel process and catalysts for the production of this military logistic fuel from light olefins derived from coal. This joint project is also looking at how to make the conversion process more energy efficient, economical, and environmentally friendly. In order to accomplish these goals, researchers are developing a new two-step process, to synthesize the liquid hydrocarbons with a high concentration of cycloparaffins and a boiling point in the range of 150 to 300 degrees Celsius (302 to 572 degrees Fahrenheit).

The advantages of this process include a resulting fuel that meets all the property requirements for JP-8; a high fuel yield of JP-8 from the light olefi ns; an energy efficient production process, as it can be conducted at relatively mild conditions; and a production process that doesn’t require additional hydrogen.

A better understanding of faults may someday help avert earthquake disasters

Graduate student Bryan Kaproth works at the Whipple detachment fault zone in southeastern CA. Photos courtesy of Sam Haines, post-doctoral fellow, Geosciences.

Graduate student Bryan Kaproth works at the Whipple detachment fault zone in southeastern CA. Photos courtesy of Sam Haines, post-doctoral fellow, Geosciences.

As the recent disasters in Haiti, Chile and other parts of the World have demonstrated, earthquakes can be devastating to populated regions. Understanding the factors controlling the stress state and nature of slip on major tectonic faults is a fundamental problem in earthquake physics and fault mechanics and important for earthquake hazard assessment. Demian Saffer, associate professor of Geosciences is leading a research project with Eric Kirby, associate professor of Geosciences and Chris Marone, professor of Geosciences that will provide a better understanding of the behavior and stability of mechanically weak faults.

Overall mechanical strength and slip behavior on major tectonic faults depend on the physical properties of the rock and gouge (the crushed material that accumulates from the friction between the two sides of a fault) within these fault zones. is project is a field and laboratory investigation funded by the National Science Foundation in which researchers are investigating the mechanical behavior of natural fault gouges from low angle normal faults (LANFs), which are normal faults with dips of less than forty-five degrees.

The mechanics of slip on LANFs, common throughout the southwestern United States, is one of the most significant unsolved problems in the geosciences. Normal faults with dips of less than thirty degrees should neither form nor be reactivated. Yet, these faults are documented in numerous field studies, and recent studies shows that slip on LANFs can be seismic or aseismic. In addition, LANFs appear to slip under unusually low stress, implying that they are mechanically weak. The potential for earthquakes along these faults is difficult to assess and therefore debated, mainly because of the overall low slip rates and long time span between large earthquakes.

This project is one of the first – if not the first – detailed investigations of frictional strength and stability for natural gouge from LANF systems to address questions about the absolute strength and nature of slip on these faults. Researchers are working to determine whether the gouge composition in LANFs can cause sufficient weakness to be able to explain the slip. In addition, they are looking at the frictional behavior of this fault gouge to find out if the behavior generally results in stable sliding, which would limit the potential for earthquakes along these faults.

Researchers study fuel combustion and emissions characteristics for new biomass fuels

Brad Maben, senior research technician, unloads a delivery of wood chips at the EMS Energy Institute.

As concern about carbon dioxide emissions elevates, many industries look for ways to diversify their fuel options. Consequently, the interest in using biomass feedstocks in utility and industrial boilers is increasing as these industries strive to reduce carbon dioxide emissions produced as a result of heat and power generation. Babcock & Wilcox Power Generation Group, Inc. (B&W PGG) is a leading designer, engineer, manufacturer and builder of biomass-fired bubbling fluidized bed (BFB) boilers for the utility and industrial markets, markets in which emissions limits for these boilers continue to be reduced while the variety of biomass fuels continues to expand. B&W PGG has teamed with researchers from Penn State to better understand the combustion and emissions characteristics of biomass fuels and to improve its product offering.

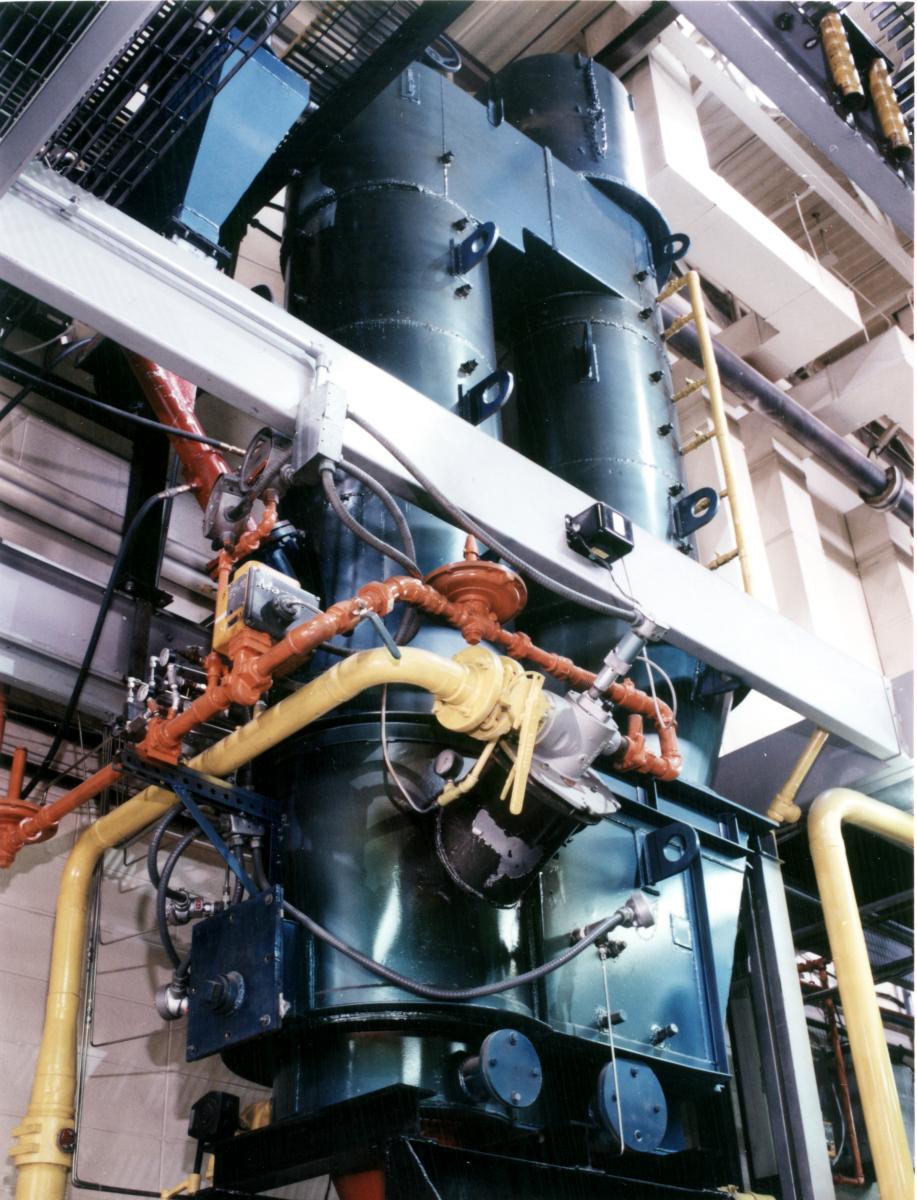

Fluidized Bed Combustor at the EMS Energy Institute.

Mr. Bruce G. Miller, senior research associate, EMS Energy Institute, is leading the research team, while several EMS Energy Institute personnel are assisting on the project, including Dr. Sharon Falcone Miller, research associate, and Mr. Ronald T. Wincek, research assistant. As part of this project, Penn State’s pilot-scale BFB combustor has undergone extensive modifications that enable it to track emissions profiles from the bed, through the combustion chamber, to the stack. This emission profile information, coupled with fuel particle size, detailed chemical analyses, and operating characteristics, will be used in a combustions/emissions model, which will allow researchers to predict a biomass fuel’s performance in a BFB boiler.

In addition, the biomass fuels, which consist of woody materials, herbaceous biomass, animal manure/litter, and other industrial processing wastes, are undergoing detailed analyses to determine the inorganic composition of biomass materials and the behavior of their constituents in a combustion environment. A variety of analytical and computational techniques are being used to assess the depositional and agglomeration behavior of the inorganic components as well as their potential impact on selective catalytic reduction (SCR) units for nitrogen oxides emissions control.