You might say Randy Vander Wal’s life work is very, very, very, very tiny. The nanoscale materials he studies are beyond the reach of even the strongest magnifying glass. But the implications of his research are vast and they stretch across many disciplines.

You might say Randy Vander Wal’s life work is very, very, very, very tiny. The nanoscale materials he studies are beyond the reach of even the strongest magnifying glass. But the implications of his research are vast and they stretch across many disciplines.

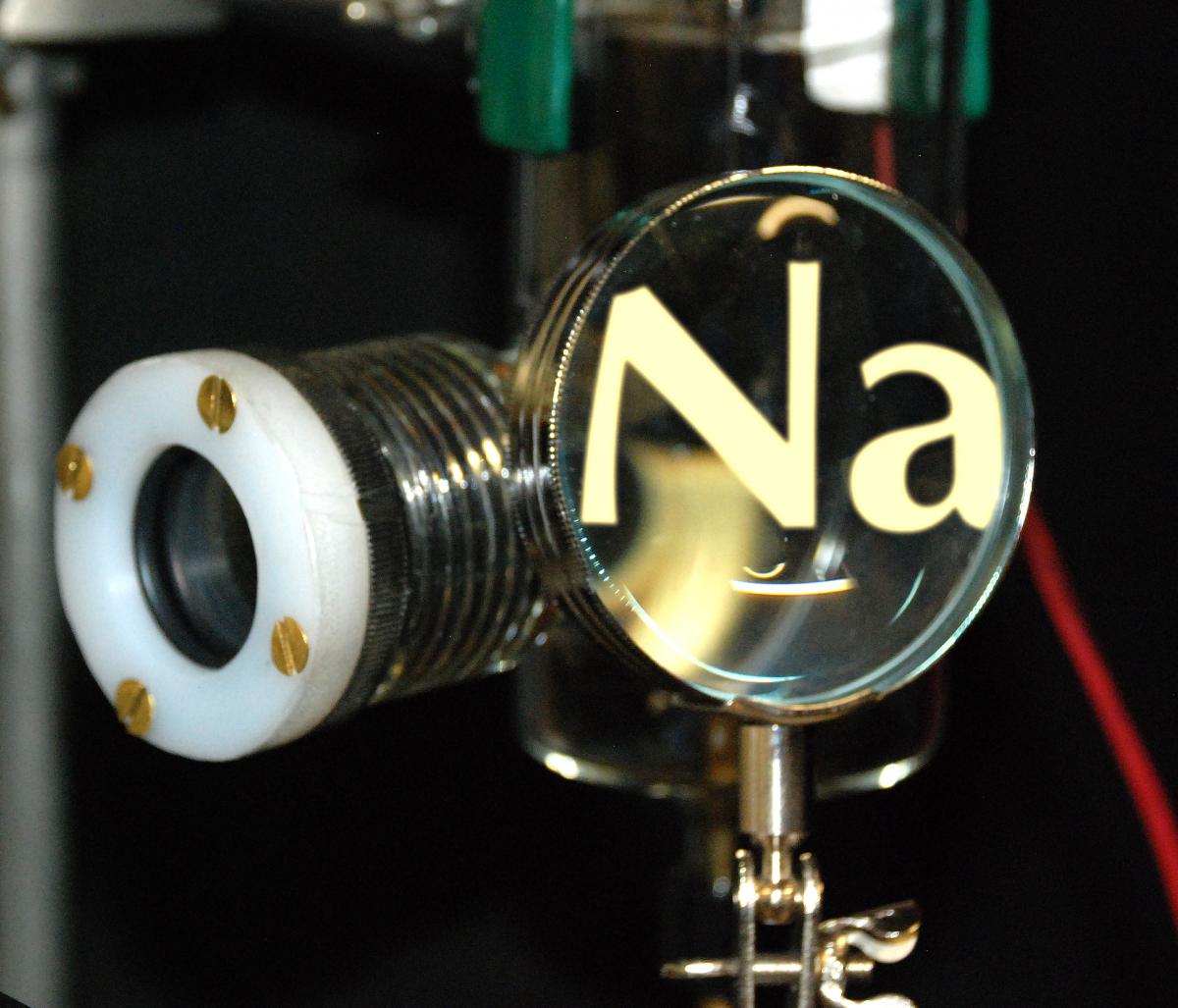

When I sat down with Randy Vander Wal, professor, energy and mineral engineering and materials science and engineering, to talk about his research, there was one question I was dying to ask. How do you use those lasers in your lab?

“I grew up using multiple lasers for spectroscopy,” Vander Wal said. “It was a very arduous task.” As a postdoctoral scholar at Sandia National Laboratory, he continued working in laser spectroscopy, a technique in which lasers are used to excite a sample, allowing the researcher to analyze the range of electromagnetic radiation emitted or absorbed by the sample.

Later, he began using lasers as an engineering tool for material processing instead of spectroscopic diagnostics. With lasers, researchers can heat materials, anneal materials, and induce phase transitions (transitions between solid, liquid, or gaseous states of matter) at incredibly fast rates. Think about the time it takes an ice cube to melt. Instead of waiting hours, minutes, or seconds – depending on the external environment – lasers can alter the state of materials in 10s of nanoseconds. To the human eye it seems instantaneous.

Vander Wal considers himself to be a diverse chemist and somewhat of an opportunist. His research varies greatly and, depending on the sponsor, ranges from soot to nanomaterials to energy. However, the more he talks about his work, the easier it is to see how each of these areas is connected.

“I consider the periodic table as the playground and build from there,” Vander Wal said. It was the intellectual challenge that drew him to the realm of nanomaterials. While early on, he had considered work in the fields of astrophysics or nuclear physics, instead he worked as an engineer at NASA for 18 years. Vander Wal received bachelor degrees in physics, chemistry, and math at Calvin College and completed his doctoral degree in chemical physics at the University of Wisconsin.

Prior to coming to Penn State, the focus of Vander Wal’s work was on space and aeronautics research as he managed a contract research group at the NASA-Glenn Research Center in Cleveland, Ohio. The group worked on batteries, sensors, composites, laser diagnostics, and more. The space research, for example, focused on the needs for long-term human sustainability in space. What is needed for a closed-loop system? What problems could arise on the surface of Mars or the moon and how could they use resources at hand for long-duration stays without resupply? Work also included testing nanomaterials for applications such as lubrication in satellites and solar sails, which require dry lubricants that are radiation resistant, heat tolerant, and last for decades – essentially the lifetime of the device.

Vander Wal has been immersed in nanomaterial research for at least the last dozen years with research ranging from the synthesis of “nanocarbons” to metal oxide semiconductors. Strictly speaking, nanomaterials are materials with two dimensions less than 100 nanometers (a nanometer is 100,000 times smaller than the diameter of a typical human hair). Nanomaterials can be engineered, but they also exist in nature and have been in existence, quite literally, since the dawn of time. Carbon black, a product of the incomplete combustion of heavy petroleum byproducts, has been around for nearly 100 years and used for core applications such as reinforcing rubber products and in more recent times, conductive plastics, toner, etc. While Vander Wal noted carbon black is not technically considered a nanomaterial, it’s on that scale. Nanomaterials also have a long history in catalysis research, although the term dispersion was historically used to describe how finely divided the catalyst particles were.

“I consider the periodic table as the playground and build from there.”

Since nanomaterials are too small to be seen even with conventional microscopes, finding and characterizing these particles has only been possible in recent decades with the help of new tools. But, as if to make up for lost time, the number of applications for these materials has since proliferated. Just walking through your house, you could touch dozens of items that contain nanomaterials, linoleum floor tiling, cosmetics, car body parts, paints, and common medications. Many food products use nanoscale silica as a binder, and nanoparticles of titanium dioxide or zinc oxide are what makes sunscreens appear white. Additives in the form of nanoparticles enhance various properties of materials, making them stronger or tougher, or conductive as in antistatic packaging.

In order to really understand how nanomaterials work, one has to look at surface area and related surface properties instead of focusing on a strict size classification. The fundamental principle that nanomaterials rely on is – the smaller the particle size, the higher the surface area. The classic example is to take one cubic centimeter of material and finely divide it into small cubes, each cube one nanometer in size. The result would be a billion trillion cubes with a combined surface area equivalent to that of a football field. A general hallmark of nanomaterials is that the surface area is vastly magnified from that of a solid material of the same mass.

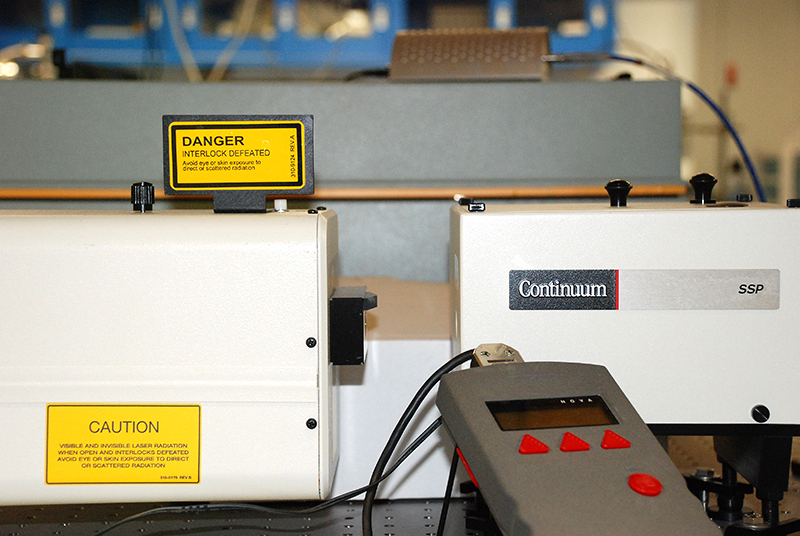

Laser equipment in Dr. Vander Wal’s research lab

The idea of surface area is very important to understanding how nanomaterials fit into the energy field. Since coming to Penn State, Vander Wal’s focus has been on the intersection between energy and nanomaterials.

“Why is there an intersection? How do they even fit together? Usually when people think about energy, they think about combustion, but nanomaterials are generally valuable, something you don’t necessarily want to burn,” Vander Wal said. He explains that most energy processes occur at an interface and, since nanomaterials have large amounts of interfacial surface area, nanomaterials can serve as interfacial modifiers. When those processes occur at multiple interfaces the result can be faster reaction times, better performance, and longer lifetimes.

One good example of how this concept can transfer into energy applications lies in batteries. Picture a battery as a brick of material. The transport of energy would be extremely slow through that solid material. But if you could subdivide that brick into billions of sheets or layers you could achieve a much faster reaction rate because the higher surface area enables faster charging or discharging of the battery. In addition to batteries, nanomaterials can enhance the performance of materials used in every energy process from harvesting and generation to storage and transfer. Just a few of these applications could include enhancing materials for the harsh environments in the oil and gas industry, fuels cells for vehicles, new catalysts for petrochemicals, and efficient solar cells sustainable energy.

Vander Wal’s “environmental niche” lies in soot analysis with the goal of making combustion environmentally friendly, or better yet, health friendly.

“If you look at soot closely enough – the nanostructure – you can start to understand how it’s formed,” Vander Wal said. “ And if you understand how it’s formed, you might be able to design a process, or alter a process that results in less soot.”

One of Vander Wal’s graduate students, Chung-Hsuan Huang, has been looking at soot from jet aircraft using alternative fuels. While the government is very interested in fuels from alternative sources, other than petroleum, what those fuels produce in terms of particulate soot is essentially unknown and uncharacterized. Certainly these emissions have implications for the environment, but there is also a concern about human health. We don’t know what are we breathing at the airport. If you smell “exhaust” (incomplete combustion gases), it’s more than likely you are breathing some particulate and the smaller it is, the worse it is for your health.

Vander Wal has also proposed looking at the health and safety effects of exposure to nanomaterials in manufacturing. As applications for nanomaterials continue to increase, there is a concern about absorption through the skin or accumulation in the lungs for workers since the particles are so small. Beyond that, he continues to look for opportunities to collaborate on research.

Talking to Vander Wal, I can see how absorbed he is in his research. And he believe that as a professor, he can instill that passion and interest in his students as well. He emphasizes that to be successful and find fulfillment, researchers have to be creative and highly engaged, and approach their work with the mindset of “I like thinking about this.”

Chung-Hsuan Huang, a graduate student, works in Dr. Vander Wal’s lab at the EMS Energy Institute.