Cutting edge research to continue at Penn State with acquisition of new X-Ray CT Scanner

Rock – bone – fossilized bone – chocolate – baseball bats – baseballs – golf balls – helicopter blades – fish – fruits – vegetables – insects – plants – soil. By creating digital visualization of countless objects through non-destructive inspection, Penn State’s X-Ray CT Scanner instrument unites research areas across campus. The list will continue to grow with the acquisition of a new version of the machine, set to arrive on campus sometime this fall.

“What drives the passion about preserving these imaging capabilities and going even further is really the breadth of the applications that it has,” Zuleima Karpyn, an associate professor of petroleum and natural gas engineering, said. “All of us working with the instrument have the opportunity to work with people outside of our field and share the capabilities of the instrument.”

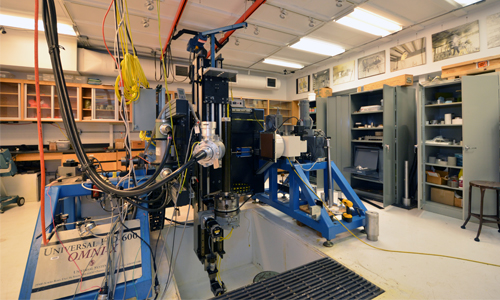

Karpyn said that one of the reasons funds could be leveraged for the new instrument is because it engages multiple colleges within the university and also outside entities. The scanner’s ability to reveal the internal components of objects through digital recreations can be applied to everything from petroleum and natural gas engineering to anthropology. When Penn acquired it 13 years ago, the instrument was one of three of its kind in the world. The application and prevalence of similar CT scanners has grown substantially since.

Mechanics of digital visualization

Tim Stecko, said the current machine works by rotating samples and capturing images of what the X-Ray shadow looks like at each perspective. Typically samples are moved 360 degrees, up and down, and around 70 to 100 images are taken. He said there are two X-Ray tubes, of higher and lower power, that are utilized based on size and density of the objects being scanned.

For example, a large fossilized mammal tooth that came through the lab, which is impregnated with minerals and materials that make it less translucent, would require the use of the higher energy tube. Stecko said that large objects are slid closer to the detector, creating a smaller shadow.

“Just like if you want to cast a shadow of a hand on the wall,” Stecko said. “If you move it closer to the light source that shadow will be much larger.” A computer uses algorithms to synchronize the position and rotation data to assemble image stacks, which are then formed into the reconstructions.

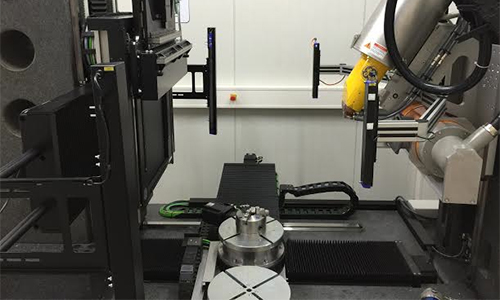

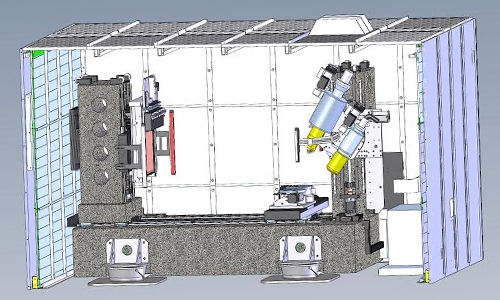

The new scanner will have the ability to be shifted between four quadrants, Stecko said, effectively doubling the size and producing a much higher resolution. The current scanner works on a level of 10 microns, Stecko said, and the new scanner will be able to work at 1 micron. “With one micron we may be able to see fine grains within the shale that would allow us to see cracks that aren’t visible in the scans we’re doing now,” Stecko said.

Additionally, Stecko said, the new instrument uses far less energy, which will allow for more data to be collected faster. Currently the shortest rotations are completed in about three and a half minutes. Stecko said the new machine would collect similar data in one tenth of the time due to the sensitivity of the detector.

Karpyn said the plan is to engage students more with the new scanner, rather than only having a trained person using it. She said this system is more approachable the user, in addition to creating higher quality, finer resolution images.

Door to new research opportunities

The new instrument will be housed at the Coal Utilization Laboratory, along with a sample preparation area and offices, Karpyn said. The renovations are planned to be finished in August and some components of the machine are set to arrive in September. Karpyn said the scanner itself sits on a granite slab weighing approximately 19,000 pounds, which will arrive first. The rest of the components will be brought in and assembled on site. Karpyn said there will be an open house to celebrate the arrival of the machine. There will also be workshops related to its different applications, with sample scanning, in an attempt to get people engaged.

Around 2012, Karpyn said, it became clear the old instrument was aging and her team began to think seriously about an update plan. The new instrument was acquired after a few different attempts, including submitting a proposal to the National Science Foundation. Ultimately, the Office of the Vice President of Research put forth a proposal to invest five million dollars of university dollars for instrumentation, with an emphasis on energy and environmental applications, Karpyn said. The history of the current machine was key in creating a proposal for the new CT scanner.

“We could not only demonstrate how much value we could bring to the university by having this new instrument acquisition,” Karpyn said. “There was a clear need based on how old the current system is and how many projects that instrument supports.” Karpyn said she was also able to partner with GE, the machine’s manufacturer, keeping the cost down and stretching the 5 million dollars from the university.

It’s a door for inspiration that is becoming part of our network of instrumentation,” Karpyn said.

Innovations in application

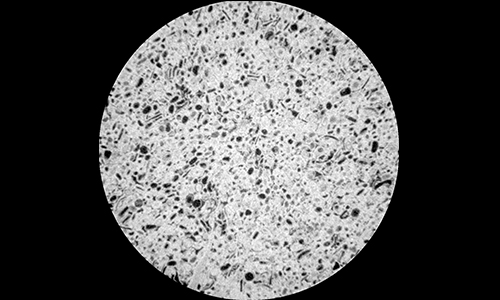

Tim Ryan, associate professor of anthropology, said he uses the scanner to characterize structure in biological and anthropologically relevant items. He said he is particularly interested in the internal bone structure.

“3-dimensional arrangement varies between different parts of your body and varies between different species and different individuals,” Ryan said. “What we use CT scans for is to collect the high-resolution data and then quantify variation of this structure.”

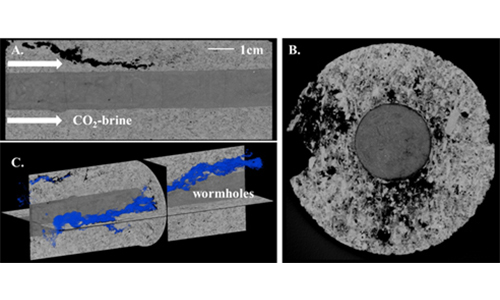

Stecko said another type of research performed involves scanning something, changing the conditions and comparing the way different things react to the changes. This process often allows you to see things you don’t expect. On one occasion, a group of Scandinavian graduate students was using the scanner to test chalk samples from the North Sea.

Stecko said they started flooding brine and the CO2 into the chalk and employed image subtraction to see the comparisons. He said they take images before and after flooding and a program lines them up and subtracts all of the CT values. If the images are exactly the same, they should zero out and you would see nothing. The group found that the chalk was expanding, which was an unforeseen outcome and is important for the research.

Stecko said that one of his favorite aspects of his job his being able to help with getting different types of experiments set up. He said he is able to see the wide range of research applications the scanner has firsthand.