There are few places on the University Park campus where Penn State researchers examining biological samples and synthetic materials intersect and are supported by one piece of technology. A micro-computed tomography or “microCT” scanner housed in the Center for Quantitative Imaging (CQI), a section of the EMS Energy Institute, allows researchers across disciplines to examine the structure of objects the size of a femur bone to freeze-dried carrots.

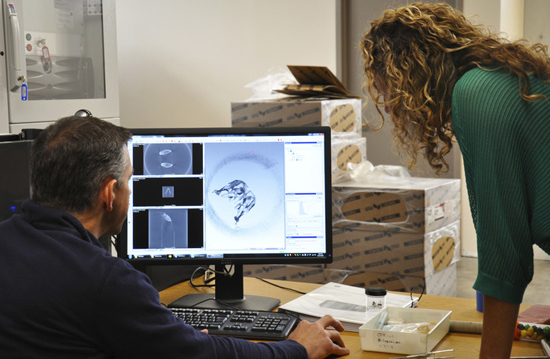

Center for Quantitative X-ray Imaging co-directors Tim Ryan and Zuleima Karpyn view a 3D image scanned on the center’s new high-resolution scanner.

Image: Angela Kendall

“The range of projects that we get to work on is very broad,” said Zuleima Karpyn, co-director of CQI and professor of petroleum and natural gas engineering. The scanner demonstrates true cross-disciplinary and cross-departmental collaboration at the University. While CQI is housed within the EMS Energy Institute, the lab is managed and operated as a core research facility of the Energy and Environmental Sustainability Laboratories within the Institutes for Energy and the Environment and the instrument is used by researchers across Penn State.

“That makes for a very nice space for interaction with different fields and research areas in different corners of the University, while having a common theme of image analysis and data science,” Karpyn said.

Traditional ways of examining the internal structure of an object, especially such dense objects as bones or rocks, required the object to be cut or broken open. That technique could cause irreparable damage to an artifact or fossil thus ending the research potential for the object or restricting researchers to only examine objects deemed acceptable to lose, said Tim Ryan, co-director of CQI and associate professor of anthropology.

The introduction of x-ray technology allowed researchers to see a two-dimensional representation of the internal structure without damaging an object but offered only limited views. CT scanners removed that roadblock by taking hundreds or thousands of 2-D images of a rotating mounted object and using them to create a 3-D digital replica of the object. The final images are viewed in a way similar to a flip book with the ability to drag the image’s x- and y-axis along one another to examine the scanned object’s length, width, and depth.

“That’s the power of CT,” Ryan said. “It’s x-ray vision because it allows us to see inside objects without destroying them.”

Beginning in the 1970s, CT technology was widely used in a medical context and by the early 1990s the industrial sector was using microCT imaging. With almost thirty years of advancements, microCT imaging now allows researchers to view the micro and even nanostructure of an object while avoiding any risk of damage.

“It’s really a big leap because before we would have to take multiple scans, maybe use different types of instruments, and do it in multiple sections, but now we can do it in true 3-D with this contrast enhancement and improved image quality,” Ryan said. The improved tool cuts down on the time and resources required to get the level of data and high-quality images the new scanner can capture.

The system is often used to analyze biological material—one project investigated evolutionary changes in the human skeleton by comparing the amount and distribution of bone in modern and fossilized humans. Differentiating between hard and soft tissues is critical to this work which the scanner provides through enhanced resolution capabilities and improved preparation techniques including the injection of contrast agents before a sample is scanned.

Despite CT technology’s roots in the medical field, micro imaging is an important tool for researchers across many disciplines.

Many of Karpyn’s graduate students work with the scanner by integrating imaging capability with experimentation. They rely on the system’s speed and accuracy to capture time sensitive experiments analyzing the properties of gas and liquids in relation to porous solids. One student is using CT images to map how gas is transported through different shale samples to identify and quantify their storage capacity and transfer properties. Another student is attempting to improve oil production by experimenting with chemically-tuned water-flooding as a form of enhanced oil recovery.

The range of projects does not surprise Karpyn or Ryan who have seen samples ranging from mice to fossil plants to human skulls being scanned.

“At times it’s not unusual where we want to scan a specimen, maybe a synthetic material for either manufacturing purposes or for construction purposes, and we apply techniques to analyze data that are similar to what you would apply in the life sciences to differentiate different textures, different materials, identify structure,” Karpyn said.

The CQI lab was established in 2001 as a formal program for CT imaging at Penn State, but the University had been using the technology for years prior as one of the few universities in America to install an industrial-scale scanner. In the almost two decades since, CT scanners have become more common in North American universities.

“Most major universities have some variety of a CT scanner,” Ryan said. “Not all of them are like ours though—not as big or as flexible in terms of its capabilities.”

The current scanner, a General Electric v|tome|x L300 multi-scale nano/microCT, brought to Penn State in 2015 after a past scanner became outdated, provides University researchers with the latest in x-ray imaging technology. A dual-tube system equipped with two powerful x-ray tubes and a high contrast digital flat panel detector allows objects of various sizes and densities to be scanned with a maximum feature detectability of 1 mm. The scanner’s size and flexibility allows for high-resolution scans of hard, soft, natural, or synthetic opaque materials along with bone and tissue samples.

“It’s that flexibility that our scanner has that many scanners don’t have,” Ryan said. “We have the facilities, the instrumentation facilities here to do really innovative work.”

The availability of imaging technology provides training and learning opportunities for faculty and students around the country that Ryan says may eventually benefit Penn State. The University’s CQI program and its capabilities can attract young scholars or faculty who have previously been trained in the context of CT and wish to continue their research or need additional resources.

“The scanner works as a core research facility for the University,” Karpyn said. “We have clients and users that are faculty or graduate students that come from different fields—from agriculture, from geosciences, from anthropology as well, from engineering.”

Clients and researchers outside of Penn State have also recognized the scanner’s abilities. Since its installation, Ryan said the lab has received requests from researchers across the country to visit campus and use the device. Others who cannot travel to University Park, including international researchers, have sent materials or museum artifacts to be scanned and the data then uploaded to an online repository where many researchers can examine the results. Outside companies have also used the tool to scan their products including batteries and snack foods.

While the instrument is housed within the EMS Energy Institute, the community of users and those who benefit from data obtained reaches far outside of the institute.

GE v|tome|x L300 multi-scale nano/microCT system

“I’ve been associated with the [EMS] Energy Institute for fifteen years, but I don’t do energy research,” Ryan said. “So that’s a great testament to the fact that this type of instrument is so useful and [provides such diverse uses] that we can bring people together from all over campus. That’s where you can have really good collaborative and transdisciplinary research projects that [are available with] these types of instruments.”

To learn more about the microCT scanner, to request lab time to use the scanner, or to learn more about the CQI program, visit eesl.iee.psu.edu.