The EMS Energy Institute’s laboratories house a variety of analytical and computational facilities, laboratory reactors, imaging equipment, and several pilot- and laboratory-scale stationary combustion, gasification, coking, and hydrocarbon recovery from sands systems. These facilities are specially designed for each of our research areas; however, many of our analyzers and instrumentation are useful in other research areas and are available for use by any faculty, staff, or student in the University community. In order to make researchers aware of our instrumentation and its capabilities, the Institute is holding free workshops. We can also offer individual training or tours at any time. To view all of our facilities, please visit www.energy.psu.edu/facilities.

Infrared spectroscopy facilities

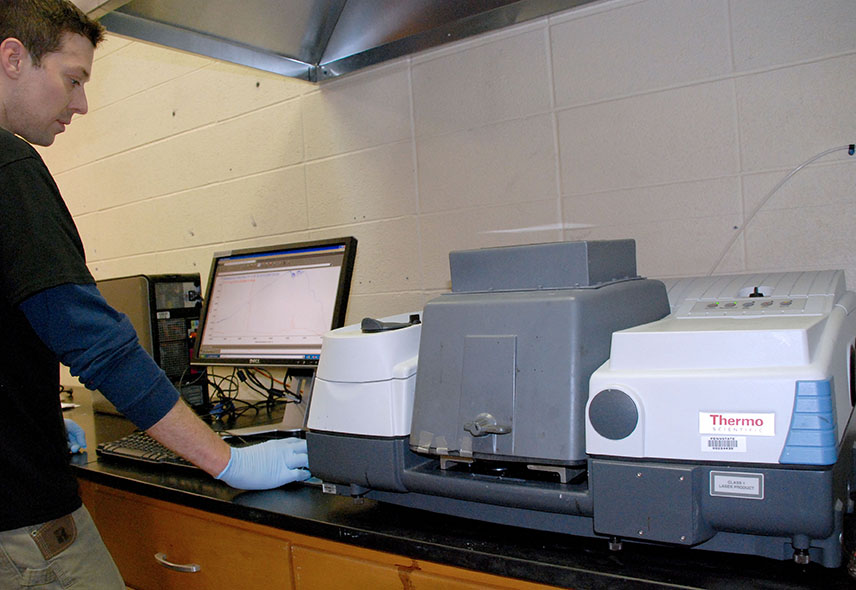

Commercial infrared spectrometers became key pieces of equipment in polymer synthesis laboratories after the Second World War and infrared spectroscopy continues to be a useful technique for certain analytical tasks. Paul Painter, professor emeritus of polymer science, directs the FTIR (Fourier Transform Infrared) spectroscopy facilities now housed at the EMS Energy Institute. These facilities, which were moved to the Institute in 2014, greatly enhance our analytical capabilities.

Infrared spectroscopy is a technique that provides a sort of “fingerprint” of molecules. Infrared light is absorbed at particular frequencies (usually reported as wavenumbers, cm-1) according to the types of chemical groups present. Researchers can measure how much light has been absorbed at each frequency by comparing intensities to light from the source that hasn’t passed through the sample to identify the microstructure of a molecule.

Although FTIR spectroscopy is used routinely in polymer science, it has applications in other fields, including energy. Currently, researchers are using the Institute’s FTIR facilities to support a project to extract hydrocarbons from sand and other materials using ionic liquids. Infrared spectroscopy allows the researchers to analyze the materials’ structures before and after cleaning with ionic liquids.

Chromatography and spectroscopy analyzers

Chromatography is a separation technique widely used in analytical chemistry that enables the detection, identification, and quantification of individual species in a complex mixture. It is the most versatile and widely used technique for the separation and analysis of thermally stable and volatile organic and inorganic compounds. Small quantities of material can be separated and identified qualitatively and quantitatively. In the last 60 years, the applications of chromatography have grown extensively with the invention of sensitive detectors and highly specialized electronics and microprocessors.

The EMS Energy Institute has a diverse selection of gas chromatography techniques at its disposal. The Analytical Research Group at the EMS Energy Institute oversees the maintenance, scheduling, and use of this suite of chromatography and spectroscopy equipment. The majority of these technologies are focused on the detection and speciation of complex hydrocarbon mixtures. For example, analyzers can identify specific sulfur and nitrogen compounds in diesel fuels, analyze liquid fuels obtained from coal and biomass conversion processes, or measure the concentration of specific compounds in the emissions from flue gas.

In April and May 2014, the EMS Energy Institute held the first open workshops to highlight this instrumentation and its uses. The workshops provided an overview of chromatographic technique and applications as well as information on how chromatography can be a powerful detection tool when used with other techniques, such as mass spectroscopy or high performance liquid chromatography. The workshops also included a tour of the analyzer laboratory. The workshops were well attended by researchers from a variety of departments, including Geosciences, Mechanical and Nuclear Engineering, Chemistry, Biology, Agricultural and Biological Engineering, Animal Science, Plant Science, and Energy and Mineral Engineering.

X-ray CT imaging for research

X-ray CT is a method for mapping X-ray absorption to provide non-destructive 3D images of the interior structure of objects. In its simplest form, a computer combines images of an object taken from many directions. The result is a 2D grid of numbers representing X-ray absorption of individual area or volume elements inside the sample. These slices can be stacked together to obtain 3D images. Because X-ray absorption depends on density and atomic number, the data can be interpreted in terms of density, porosity, fluid saturation, or component ratios.

X-ray CT is a method for mapping X-ray absorption to provide non-destructive 3D images of the interior structure of objects. In its simplest form, a computer combines images of an object taken from many directions. The result is a 2D grid of numbers representing X-ray absorption of individual area or volume elements inside the sample. These slices can be stacked together to obtain 3D images. Because X-ray absorption depends on density and atomic number, the data can be interpreted in terms of density, porosity, fluid saturation, or component ratios.

The Center for Quantitative Imaging (CQI), which is located in the Institute, maintains an industrial X-ray CT scanner and a variety of associated equipment, including high-precision pumps, X-ray transparent core holders, high-precision quartz pressure transducers, and specially designed pressure vessels. This facility provides non-destructive imaging services to advance scientific knowledge and improve industrial manufacturing processes.

X-ray imaging has applications in many areas, including biological and anthropological studies; geological research, such petroleum and natural gas studies and carbon sequestration studies; and materials research.

Recently, CQI held a two-day short course on X-ray CT imaging of geo-materials with Dr. Phil Halleck, associate professor emeritus of energy and mineral engineering. The purpose of the course was to acquaint graduate students and researchers with basic principles of X-ray CT imaging and its application in the structural and compositional characterization of rocks, soils, and other similar porous materials. The course was captured on video as well for later viewing by researchers interested in using X-ray CT imaging in their work. For more information on the capabilities of CQI, please visit iee.psu.edu/labs/center-quantitative-imaging.

Recently, CQI held a two-day short course on X-ray CT imaging of geo-materials with Dr. Phil Halleck, associate professor emeritus of energy and mineral engineering. The purpose of the course was to acquaint graduate students and researchers with basic principles of X-ray CT imaging and its application in the structural and compositional characterization of rocks, soils, and other similar porous materials. The course was captured on video as well for later viewing by researchers interested in using X-ray CT imaging in their work. For more information on the capabilities of CQI, please visit iee.psu.edu/labs/center-quantitative-imaging.