From exploring alternative energy sources to developing new technologies for the production, generation, and utilization of energy, the EMS Energy Institute is involved in almost every aspect of energy research. This section highlights the diversity of some of our ongoing projects.

Using Polarized-light Microscopy to Assess Coke Quality for Manufacturing Carbon Anodes and Graphite Electrodes

-- Contributed by Semih Eser

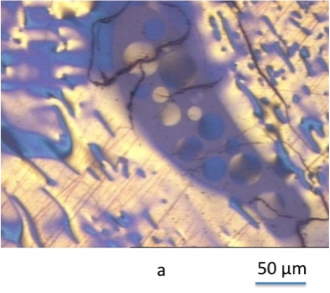

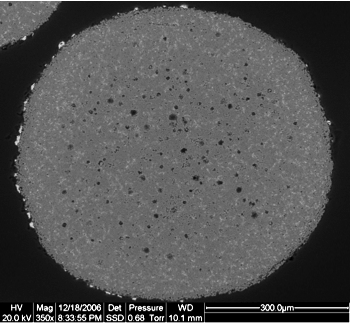

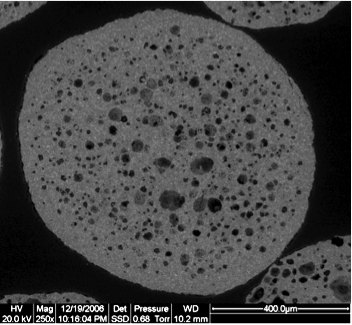

Semih Eser, professor, energy and geo-environmental engineering, and co-workers Ronald T. Wincek, graduate student, and Gareth D. Mitchell, research associate, EMS Energy Institute, have been working on a project funded by Foster Wheeler USA Corporation that combines laboratory-scale and pilot-plant coking experiments using various feedstock materials. Coke samples produced from these experiments are embedded in epoxy resin and polished for examination under a polarized-light microscope.

Semih Eser, professor, energy and geo-environmental engineering, and co-workers Ronald T. Wincek, graduate student, and Gareth D. Mitchell, research associate, EMS Energy Institute, have been working on a project funded by Foster Wheeler USA Corporation that combines laboratory-scale and pilot-plant coking experiments using various feedstock materials. Coke samples produced from these experiments are embedded in epoxy resin and polished for examination under a polarized-light microscope.

Using a protocol developed by Eser, polished sections of the cokes are examined to generate optical texture data for assessment of the microstructural anisotropy of the coke samples. Structural anisotropy of the cokes results from the development of a liquid crystalline phase (carbonaceous mesophase) during coking, or carbonization. Two focus areas in this project include studying the role of feed components in mesophase development (formation of the coke texture) and seeking relationships between the coking conditions and the texture (microstructural anisotropy) of the resulting cokes. Microstructural anisotropy determines the properties of cokes that are critically important for manufacturing graphite electrodes from these cokes.

Using a protocol developed by Eser, polished sections of the cokes are examined to generate optical texture data for assessment of the microstructural anisotropy of the coke samples. Structural anisotropy of the cokes results from the development of a liquid crystalline phase (carbonaceous mesophase) during coking, or carbonization. Two focus areas in this project include studying the role of feed components in mesophase development (formation of the coke texture) and seeking relationships between the coking conditions and the texture (microstructural anisotropy) of the resulting cokes. Microstructural anisotropy determines the properties of cokes that are critically important for manufacturing graphite electrodes from these cokes.

Eser traveled to Beijing in October 2012 to meet with officials of PetroChina Northeast Refining & Chemical Engineering Co., Ltd. for discussions on starting a research project at EMS Energy Institute on delayed coking of petroleum fractions. The project is likely to start in Summer 2013.

These polarized-light micrographs are examples of optical textures of semi-cokes obtained from laboratory experiments.

Coal Molecular Modeling—Light at the End of the Tunnel

-- Contributed by Jonathan Mathews

The ability to explore and predict behavior through atomistic simulations has altered scientific progression. Unfortunately, coal science has perhaps the greatest challenge in capturing the structural features, or to be more specific, the distribution of structural features that contributes to the apparent structural continuum.

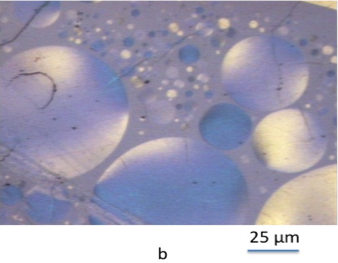

Jonathan Mathews, associate professor, energy and mineral engineering, along with other Institute researchers have progressed the capturing and creation of coal and char structures using new approaches so that transformations and behavior can be explored. With the advances made by numerous EMS Energy Institute graduate students, colleagues, and other collaborators there is light at the end of the tunnel -- the use of atomistic structures in a meaningful manner. These advancements are centered on capturing the distributions of structural features.

With large-scale models or structures (>50,000 atoms) there is a change in the construction paradigm. Rather than using an inefficient and repetitive trial and error approach, Institute researchers use image analysis of high resolution transmission electron microscopy (HRTEM) lattice fringe micrographs to directly capture the aromatic structure of the coal samples. Using HRTEM imaging information, the structure is manipulated through scripting approaches to add heteroatoms that have the desired functionality. Model structures can then be used to determine theoretical analytical data, including pore size distribution, stacking, and orientation. The theoretical data can then be used to conform to actual experimental analytical values to aid in improving the model structure. This approach results in structures that are much larger and more accurate. In addition, construction of the structures takes hours or days, rather than months, leaving time to be invested in the scientific exploration of utilizing the structures rather than in the construction.

The figure below shows a montage of work demonstrating researcher’s advances in structural representations, visualization, and utility. In collaboration with Adri van Duin, associate professor, mechanical engineering, and his group, reactive simulations are done on the model structures. To date, Institute researcher’s have investigated pyrolysis of coal and combustion of char structures using high performance computing. They also explore the kinetics of liquefaction and dissolution with coal. Using these computational techniques, these researchers explore the optimization of experimental research and maximize the potential of that most wonderful black rock—coal!

a) HRTEM lattice micrograph of coal, b) Slice model duplicating HRTEM observations (with added oxygen), c) Complexity of a structural distribution for a 50,000 atom representation (Illinois no. 6 bituminous coal), d) Lattice view of the same structure capturing the cross-linking with nodes being the hydroaromatic structure.

a) HRTEM lattice micrograph of coal, b) Slice model duplicating HRTEM observations (with added oxygen), c) Complexity of a structural distribution for a 50,000 atom representation (Illinois no. 6 bituminous coal), d) Lattice view of the same structure capturing the cross-linking with nodes being the hydroaromatic structure.

Development of High Performance Proppants for Stimulation of Oil and Gas Shales

-- Contributed by John Hellmann

The goal in hydrofracturing and stimulation of gas and oil wells is maintaining high permeability paths for resource recovery over the life of the well. This goal is commonly achieved with a slurry of surfactants, corrosives, and ceramic aggregates injected under pressure to induce and maintain fractures emanating from the well bore. The aggregates, or proppants, are pinned by closure stresses after the hydrofracturing pressure has been relieved, and “prop” the fracture open, thereby providing a permeable pathway for oil and gas to migrate to the well bore for subsequent extraction.

The goal in hydrofracturing and stimulation of gas and oil wells is maintaining high permeability paths for resource recovery over the life of the well. This goal is commonly achieved with a slurry of surfactants, corrosives, and ceramic aggregates injected under pressure to induce and maintain fractures emanating from the well bore. The aggregates, or proppants, are pinned by closure stresses after the hydrofracturing pressure has been relieved, and “prop” the fracture open, thereby providing a permeable pathway for oil and gas to migrate to the well bore for subsequent extraction.

A wide range of materials have been employed as proppants over the years, including walnut hulls, Brady and Ottawa sands, glass, sintered bauxite and kaolin, and fused zircon. Current state-of-the-art proppants are predominantly derived from sintered high-grade bauxite. However, an increased demand for high-grade bauxite for aluminum metal production and use in industrial refractories has created a significant shortage and accompanying cost increase. The ability to manufacture high quality proppants from alternative raw materials, closer to the site of application, offers strategic benefit and substantial shipping cost savings potential.

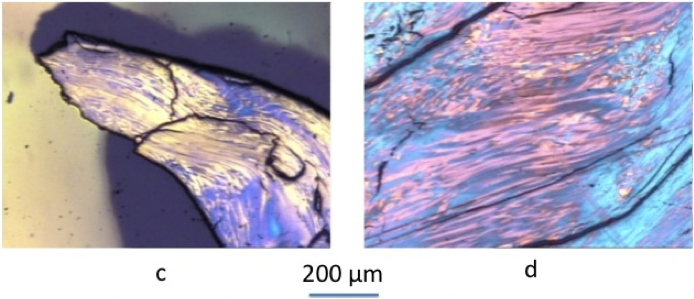

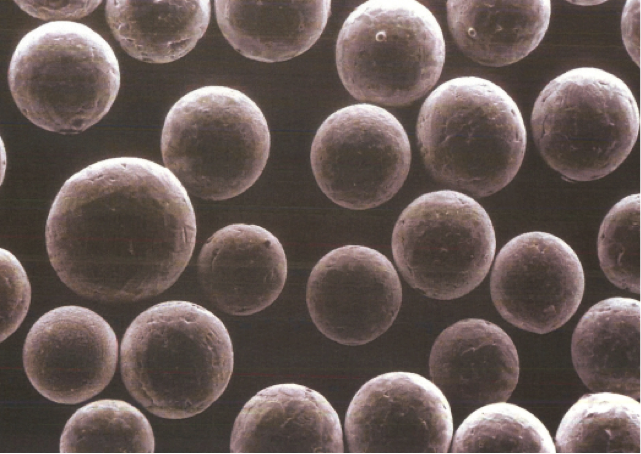

Sintered bauxite proppant possessing a coreshell structure, effective specific gravity < 1 g/cc, and high strength (diametral compressive strengths in the range of 150-300 MPa). U.S. Patent #7,828,998

Research at Penn State by Professors John Hellmann and Barry Scheetz, and their graduate students over the past ten years successfully addressed the development of high-strength proppants from a wide range of raw materials plentiful in regions in which oil and gas development is currently underway or emerging (e.g. Marcellus and Utica gas shales, the Bakken oil shales, and Eagle Ford gas and oil shales). In collaboration with a major manufacturer and worldwide supplier of proppants, Hellmann and his group developed high-strength, neutrally buoyant proppants from lower grade sintered bauxites. With the use of dopants to enhance sintering mechanisms, promote desirable microstructural evolution, and tailor surface reactivity, high performance proppants can be manufactured from these lower grade, more readily available bauxites and kaolins. In addition, they can be manufactured with a range of specific gravity that will enable their use with alternative stimulation fluids, such as supercritical carbon dioxide, allowing an entirely new stimulation technology in which environmentally sensitive additives commonly used in water-based stimulation fluids are no longer required.

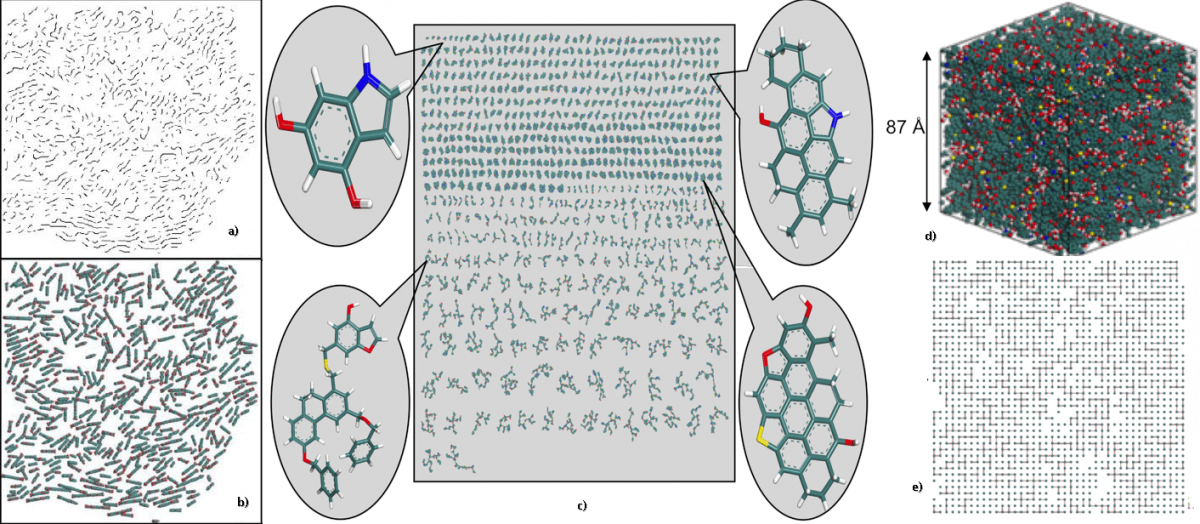

“Smart Proppants” that permit placement via magnetophoresis, re-stimulation of the proppant pack using alternating magnetic fields, and interrogation of the electromagnetic and/or acoustic response of the propped region.

Researchers have also employed industrial by-products for manufacturing high quality proppants that rival commercially available sintered bauxite-based materials in strength, hardness, specific gravity, and behavior in crush and permeability tests. These materials include chemically bonded pozzolonic materials (fly ash and slags); ion exchanged glass beads; and rhyolite, andesite and basalt-based glass-ceramics. Researchers are now extending this work to cuttings from the oil and gas well drilling process itself. Drill cuttings contain trace quantities of naturally occurring radioisotopes (referred to in the industry as Technology Enhanced Naturally Occurring Radioactive Materials – TENORMS). In addition, drill cuttings contain significant amounts of mineral oils left over from the drilling process. Therefore, the drill cuttings must be treated as residual waste and disposed of in engineered landfills. Removal of these materials from the waste stream and employing them as raw materials for proppant manufacturing offers a tremendous environmental benefit, while returning them to the geological strata from whence they came.

In related work, Hellmann and collaborators are developing “Smart Proppants”, in which the electromagnetic properties are tailorable using metamaterial design principles. These characteristics are being engineered to permit precise placement of the proppants, stimulation of the proppant, and detection of proppant placement.

Funding for this work has come from the U.S. Department of Energy, Penn State’s Stripper Well Consortium, several proppant manufacturers, and the energy industry. The results of this work are currently being licensed to a variety of proppant manufacturers and end users.