Battery metals from mine waste: Potential economic benefits for the commonwealth

Pennsylvania has a long history of mining and metallurgical activities dating to the Industrial Revolution that helped fuel the economy of the commonwealth and the nation. Coal markets have waned recently due to the transition away from coal to other energy sources, leading to many economically distressed areas in the state. New findings by a team led by Penn State researchers suggest potential economic opportunities from the domestic production of critical minerals. The team evaluated cobalt and manganese from the byproducts of mining and metallurgy from past industrial activities. Preliminary estimates indicate that waste left by coal mining activities in Pennsylvania contain tens of thousands of metric tons of cobalt and hundreds of thousands of metric tons of manganese. In addition, more than 5,500 metric tons of manganese are being discharged through acid mine drainage, with the untreated portion reaching the commonwealth’s waterways each year.

Pennsylvania has a long history of mining and metallurgical activities dating to the Industrial Revolution that helped fuel the economy of the commonwealth and the nation. Coal markets have waned recently due to the transition away from coal to other energy sources, leading to many economically distressed areas in the state. New findings by a team led by Penn State researchers suggest potential economic opportunities from the domestic production of critical minerals. The team evaluated cobalt and manganese from the byproducts of mining and metallurgy from past industrial activities. Preliminary estimates indicate that waste left by coal mining activities in Pennsylvania contain tens of thousands of metric tons of cobalt and hundreds of thousands of metric tons of manganese. In addition, more than 5,500 metric tons of manganese are being discharged through acid mine drainage, with the untreated portion reaching the commonwealth’s waterways each year.

Coal creation mechanism uncovered

The mechanism behind one of the first stages of coal creation may not be what has long been thought, according to Penn State researchers who found that microbes were responsible for coal formation and production of methane. The finding has implications for methane fuel recovery from some coal fields. The researchers looked at methoxyl groups in coal samples from around the world and used stable isotopes to show that organic material eventually becomes coal through microbial action.

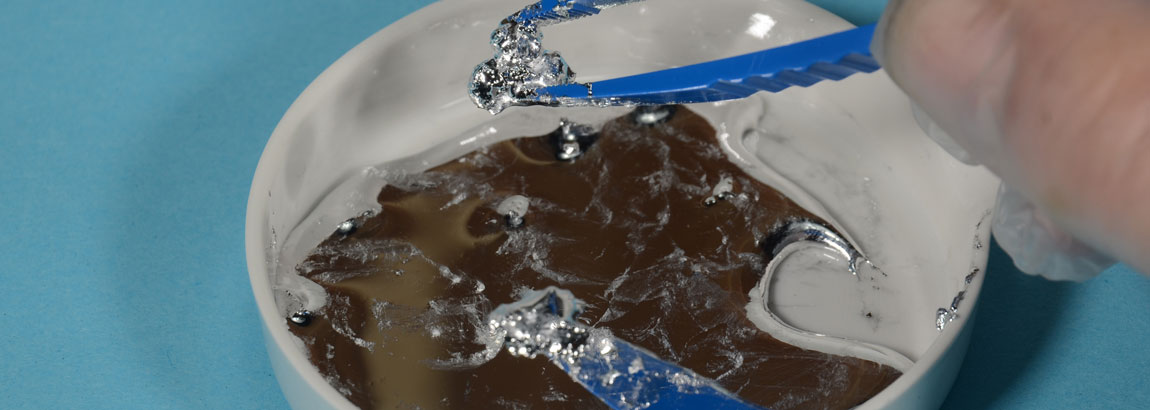

New, environmentally friendly method to extract and separate rare earth elements

A new method improves the extraction and separation of rare earth elements—a group of seventeen elements critical for technologies such as smartphones and electric car batteries—from unconventional sources. New research led by scientists at Penn State and the Lawrence Livermore National Laboratory demonstrates how a protein isolated from bacteria can provide a more environmentally friendly way to extract these metals and to separate them from other metals and from each other. The method could eventually be scaled up to help develop a domestic supply of rare earth metals from industrial waste and electronics due to be recycled.

Seismic study will help keep carbon underground

Seismic study will help keep carbon underground

Scientists from Rice University, Penn State, and the Lawrence Berkeley National Laboratory, are developing sophisticated fiber-optic sensors and seismic sources to find and evaluate small faults deep underground at sites that store carbon dioxide to keep it out of the atmosphere. The U.S. Department of Energy awarded Rice geoscientist Jonathan Ajo-Franklin $1.2 million to adapt his lab’s distributed acoustic sensing method to monitor storage sites where reactivation of small faults could allow leakage into adjacent groundwater or the atmosphere. The project is part of $4 million in grants announced in May 2021 to enhance the safety and security of carbon storage.

Penn State to lead critical minerals consortium powered by $1.2 million from DOE

A region famous for the coal that once fueled a growing nation is now the focus of a $1.2 million project, led by Penn State researchers, aimed at establishing domestic supplies of critical minerals needed to produce modern technology from cell phones to fighter jets.

Penn State will lead the Consortium to Assess Northern Appalachia Resource Yield to assess and catalog northern Appalachian-basin critical mineral resources and waste streams; develop strategies to recover the materials from these streams; and identify potential supply-chain or technology gaps that will need to be addressed. The project, funded by the U.S. Department of Energy, is part of a broader, national effort to produce rare-earth elements and critical minerals.

Institutes of Energy and the Environment director to step down

Institutes of Energy and the Environment director to step down

Tom Richard, director of the Penn State Institutes of Energy and the Environment (IEE), will step down from his position with the institutes after more than thirteen years of dedicated leadership. Richard has served as director of IEE since 2008, shortly after the IEE expanded and first adopted energy as part of the institutes’ name and mission. In that time, Richard has overseen the growth of IEE from thirty-two to seventyone co-funded faculty members with more than 500 faculty affiliates, and from less than $10 million in active research awards to more than $100 million. Richard will continue to serve Penn State as a professor of agricultural and biological engineering.

Researchers awarded grant to advance geothermal energy science

Over the last decade, geothermal energy has progressed throughout the world as an environmentally friendly, sustainable source of energy. Using the heat from the Earth’s crust, geothermal power plants harvest and store energy in massive underground reservoirs carved out of stone. Once built, the reservoirs are inaccessible and monitored remotely—but they are not infallible. Earthquakes and more can fracture the subsurface rock, risking the integrity of the reservoir and endangering energy production. Parisa Shokouhi, associate professor of engineering science and mechanics and acoustics, is working to predict possible breaks and how to mitigate the potential fallout. Her team began its work in 2017 with a grant from the U.S. Department of Energy's Basic Energy Sciences program. The program renewed the grant for a total funding amount of nearly $1.2 million.

Over the last decade, geothermal energy has progressed throughout the world as an environmentally friendly, sustainable source of energy. Using the heat from the Earth’s crust, geothermal power plants harvest and store energy in massive underground reservoirs carved out of stone. Once built, the reservoirs are inaccessible and monitored remotely—but they are not infallible. Earthquakes and more can fracture the subsurface rock, risking the integrity of the reservoir and endangering energy production. Parisa Shokouhi, associate professor of engineering science and mechanics and acoustics, is working to predict possible breaks and how to mitigate the potential fallout. Her team began its work in 2017 with a grant from the U.S. Department of Energy's Basic Energy Sciences program. The program renewed the grant for a total funding amount of nearly $1.2 million.

Grant to fund new processing techniques for Gallium extraction

Athanasios Karamalidis, assistant professor of energy and mineral engineering, was awarded the Dean’s Fund for Postdoc-Facilitated Innovation Award in the College of Earth and Mineral Sciences for his work titled “Phosphate Functionalized Cellulose Sponge for Highly Efficient Gallium Extraction and Separation from Industrial Waste.” Under his broader research efforts in the space, he and his colleagues Michael Hickner, professor at Penn State, and Timothy Ramadhar, assistant professor at Howard University, collaborate in an interdisciplinary project targeting to develop new selective adsorbents for the extraction and separation of gallium (Ga) from industrial liquid wastes. Ga is a critical mineral, which is mostly used for integrated circuits and optoelectronics, such as LEDs, and in biomedical, radiopharmaceutical, and other fields. The fact that there are no gallium-focused mines in conjunction with increasing demand for the element paints a picture of a challenging problem. Karamalidis said that the outcomes of the proposed study can serve in the development of new processing techniques for Ga extraction from industrial wastes, contributing to contemporary circular economy approaches, which will also help meet the demand of Ga in the future. The developed materials and technologies could also provide new insights for extracting other critical materials including other rare earth elements.